Therapeutic application of cells or cell-based therapy is a flourishing research field that offers a transformative approach to the healthcare industry. This type of research provides hope not only for treating incurable or rare diseases, but also the possibility to cure them. For the manufacture of cell-based therapies, cells are optimized to produce therapeutic agents. Generating an adequate number of cells with retained cell function and quality represents an essential factor for product efficacy.

One of the primary examples of cells being cultured and studied for cell-based therapy is mesenchymal stem cells or MSCs. These cells are adherent in nature, meaning that they need a surface for attachment to grow and survive. Culturing MSCs are mainly done in a flat 2D surface like flasks with little media for nourishment. This conventional way of culturing cells poses challenges once the user decides to scale-up the cell production. Culturing in 2D will also entail larger systems or a massive amount of flasks, which is both labor and time extensive. Also, process automation does not reduce costs and will require larger facility footprint to operate.

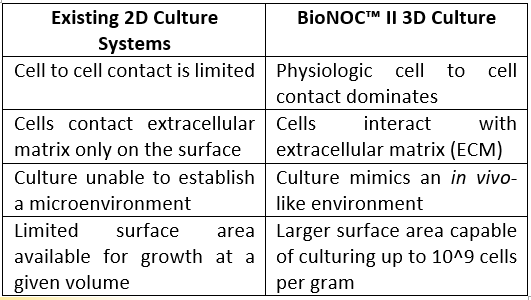

This complex process is simplified by transiting from 2D culture to 3D culture. 3D culture systems, such as the use of BioNOC™ II macrocarriers in Tide Motion bioreactors, offer a larger surface area for cell proliferation and communication. This system provides a better foundation for the bioprocessing of a target drug. Although some scientist sees the transition a challenging process, linearly scalable systems ensure product consistency and quality. For example, during scale-out, researchers started culturing cells in fifty (50) pieces of 2D flasks yielding 2x10^9. A total of 4x10^9 cells are required for the next production. Considering that the process has been established in the first phase, an additional fifty (50) 2D culture flasks will be carried to reach the target density of cells. However scaling up in 3D culture bioreactors that are linearly scalable from laboratory scale to pilot or production scale, will give off the same product quality at a higher yield with minimal parameter change. 3D culture in bioreactors significantly reduces costs and labor.

Culture System Comparison:

Another evolutionary option is better to eliminate the challenging way of developing cell-based products. Product development can start in laboratory scale 3D culture systems, rather than culturing in 2D. This process, in return, will make the cells adapt to the system, saving time and effort.

The breadth and diversity of the current cell-based therapies have shown huge consideration to the cell types involved and its clinical indications. 3D culture systems, such as the Tide Motion bioreactors, is an innovative manufacturing platform that promises progress in understanding the quality and efficiency of cell-based products. Moreover, as BioNOC™ II macrocarriers mimic the framework from where cells were isolated, 3D culture systems of VacciXcell offer a height of success for an economically, efficient product.

Reference: Smith, J. (2015, January 26). Travelling to another dimension: going from 2D to 3D cell culture [Web log post]. Retrieved November 20, 2017, from http://www.signalsblog.ca/travelling-to-another-dimension-going-from-2d-to-3d-cell-culture/.

Sign up to our newsletter and receive the latest news and updates about our products!